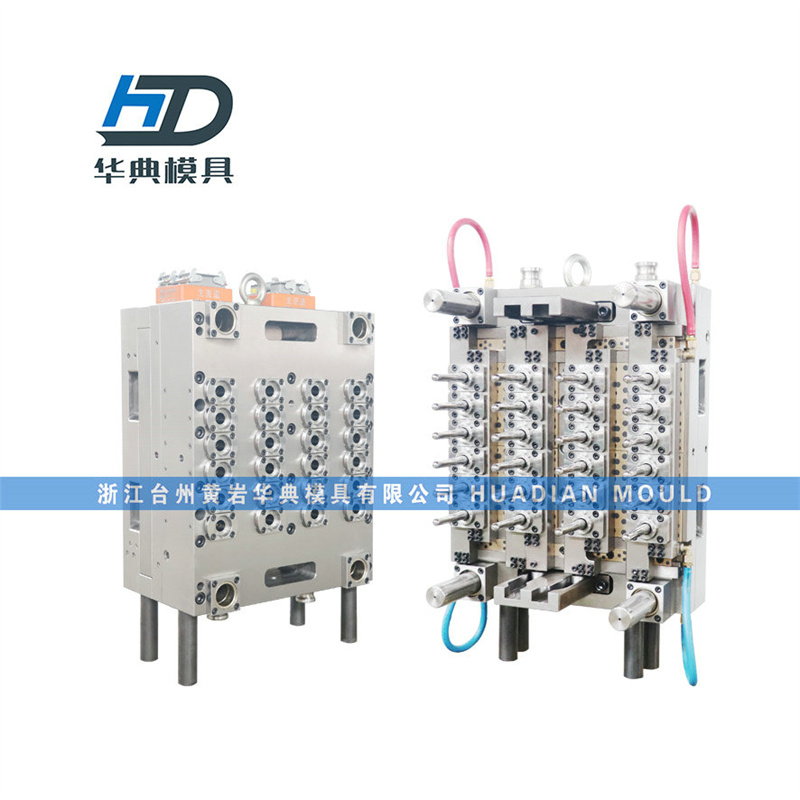

24 Cavities Disinfection Etsa Mold

Litlhaloso

| Cavity | Phetha | Boholo ba hlobo | Boima ba hlobo | Nako ea Cycle | |||

| Boima(g) | Molala(mm) | Bophahamo(mm) | Bophara(mm)) | Botenya(mm) | (kg) | (metsotsoana) | |

| 2(1*2) | 720 | 55 | 470 | 300 | 608 | 330 | 125 |

| 4(2*2) | 720 | 55 | 490 | 480 | 730 | 440 | 130 |

| 8(2*4) | 16 | 28 | 450 | 350 | 410 | 475 | 18 |

| 12(2*6) | 16 | 28 | 600 | 350 | 415 | 625 | 18 |

| 16(2*8) | 21 | 28 | 730 | 380 | 445 | 690 | 22 |

| 24(3*8) | 28 | 28 | 770 | 460 | 457 | 1070 | 28 |

| 32(4*8) | 36 | 28 | 810 | 590 | 515 | 1590 | 28 |

| 48(4*12) | 36 | 28 | 1070 | 590 | 535 | 2286 | 30 |

Molemo ho Hot Runner Technique

1. Fokotsa ho senyeha le litšenyehelo tsa thepa e tala.

2. Fokotsa mosebetsi oa ho tsosolosa, ho hlophisa, ho senya, ho omisa le ho boloka litšila, ho ntlafatsa ts'ebetso ea mosebetsi, ho boloka nako le sebaka.

3. Qoba ho sebelisa lisebelisoa tse khutlisitsoeng tse tla susumetsa boleng ba sehlahisoa.

4.Guarantee sehlahisoa ka boemo bo tšoanang ba boleng

5.Eketsa molumo oa ente, Ntlafatsa khatello ea maikutlo ea ho qhibiliha ha polasetiki

6.Eketsa mosebetsi oa ente, ntlafatsa mokhoa

7. Fokotsa nako ea ente le ho boloka khatello

8.Reduce Clamping force

9.Shorten Mold bula stroke ea ts'ebetso ea ente, Felisa nako ea ho ntša thepa ea Nozzle

10.Shorten potoloho ea ente, ntlafatsa automation le katleho ea mosebetsi

Ts'ebetso ea Bohlokoa ea Sisteme ea Semathi se Chesang

1.Laola mocheso oa polasetiki o qhibiliha hantle, Felisa ho senyeha ha thepa.

2.Naturally e leka-lekaneng semathi desgin, Mold Cavity evenly tlala.

3.Suitable boholo ba Hot Nozzle ka etsa bonnete ba hore polasetiki e qhibilihisa selefouno ka katleho 'me hlobo ea hlobo e tlatsitsoe ka ho lekana.

4.Sebopeho se nepahetseng sa heke le boholo bo ka tiisa hore sekoti sa hlobo se tlatsitsoe ka mokhoa o lekanang, Heke ea valve ea nale e koetsoe ka nako, ho khutsufatsa nako ea potoloho.

5. Ha ho na angle e shoeleng ho semathi, etsa bonnete ba ho fetola 'mala kapele, qoba ho senyeha ha thepa.

6. Fokotsa Khatello lahleheloa

7. Khatello ea ho boloka nako e loketse.

HuaDian Mold - data ea hlobo

| NO. | Lebitso | Ho nyahama | Ho thatafala | |

| 1 | Mold base material | P20 | 28-32 | |

| 2 | Core, cavity | S136 | 48-52 | |

| 3 | Molala o hohla | S136 | 48-52 | |

| 4 | Mokhoa oa ho pholisa | Koko ea hlobo, ho pholisa molala | ||

| 5 | Mokhoa oa ho pholisa bakeng sa core plate le cavity plate | 1 ho, 1 tsoa | ||

| 6 | E tsoa bohareng(MM) | "+/-0.08MM | ||

| 7 | Nako ea ente ea potoloho | 8-23 Metsotsoana | ||

| 8 | Nako ea thomello | Matsatsi a 55 ka mor'a hore li-designs li netefatsoe | ||

Theko e phahameng ea 24 cavity sterilizer hlobo ke hlobo ea boleng bo holimo e entsoeng ka lisebelisoa tsa tšepe tsa boleng bo holimo tse tšoarellang haholo le ts'ebetso e tšepahalang.E na le likheo tse entsoeng ka ente tse 24 'me e ka hlahisa li-sterilizers tse 24 ka nako e le' ngoe, tse sebetsang hantle haholo ho feta hlobo e le 'ngoe ea cavity ka nako e tšoanang ea tlhahiso.

Ho phaella moo, hlobo e amohela theknoloji le ts'ebetso e tsoetseng pele ka ho fetisisa, e le hore e be le mohaho o nepahetseng le ts'ebetso e babatsehang.Esita le tabeng ea ts'ebetso e matla ea matla, e boetse e tiisa phello e tsitsitseng ea ho sebetsa 'me e ntlafatsa haholo katleho ea tlhahiso.

Theko e phahameng ea 24 cavity sterilizer hlobo ha e loketse feela tlhahiso ea sterilizer, empa hape le bakeng sa tlhahiso ea lihlahisoa tse ling tsa polasetiki.E ka sebelisoa ho mefuta le mefuta e fapaneng ea mochini oa ho bopa ente le mela e ikemetseng ea tlhahiso, hape e ka etsoa ho latela litlhoko tsa bareki.

Ho phaella moo, hlobo ha e na molemo feela ka katleho ea tlhahiso, empa hape e ka fokotsa haholo litšenyehelo tsa tlhahiso le ho thusa bareki hore ba be le tlhōlisano ha ba tobane le tlhōlisano e matla ea 'maraka.Ka lebaka la sena, ke e 'ngoe ea likhetho tse holimo bakeng sa bahlahisi ba bangata le lik'hamphani.